Pottery identification is a valuable aid to dating of archaeological sites. Pottery is usually the most common find and potsherds are more stable than organic materials and metals. As pottery techniques and fashions have evolved so it is often possible to be very specific in terms of date and source. This Jigsaw introduction to pottery identification is intended to get you started with basic guidelines and chronology.

Manufacture: Raw Materials

- Clay – mostly derived from sedimentary deposits brought by rivers, glaciers, wind etc.

- Inclusions – often incorporated naturally into the clay (e.g. sand, shell, rock fragments), but also deliberately added (e.g. sand, crushed shell, grog). Unlike clay, such fillers do not hold water, and therefore reduce the amount of water in the pot and the shrinkage of the pot during firing.

- Water is mixed with clay to turn it into a workable medium. A higher proportion of water mixed with clay results in a liquid solution that can be added to the vessel surfaces to form a slip.

- Fuel is used to dry the pottery before being placed in a kiln, as well as for the kiln firing itself.

Firing Conditions and Colour

- Oxidising environment: there is an excess of oxygen in the kiln, causing the organic matter in the clay to be released as carbon dioxide, resulting in red or brown cores.

- After carbon burn-out, iron compounds in the clay will convert to ferric oxide and the pot will turn red, or grey if there is less iron.

- Clay with a high chalk content will turn white.

- Reducing environment: as there is no excess of oxygen, the carbon will not burn out, resulting in a grey or black colours.

- In an oxidising kiln, grey pottery will result if the pots are removed before the carbon has had time to burn out.

- Green wood thrown on to the fire towards the end of firing will produce a smoky, high-carbon, environment, also resulting in black and grey pottery.

Prehistoric Pottery

Early Neolithic Pottery (c. 4000 – 3000 BC)

- e.g. Mildenhall Pottery

- Predominately ‘S’ profile bowls with rolled rims and carinated shoulders.

- Round bases and angular shoulders.

- Decoration on some bowls, more later in the period.

- Flint tempered.

- Rolled or thickened rims.

- Rims may be decorated with oblique or trans parallel incisions or impressions.

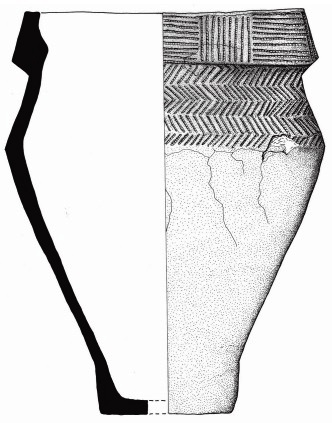

- Decoration on neck parallel vertical incisions. Flint-tempered Mildenhall pottery

Flint-tempered Mildenhall pottery

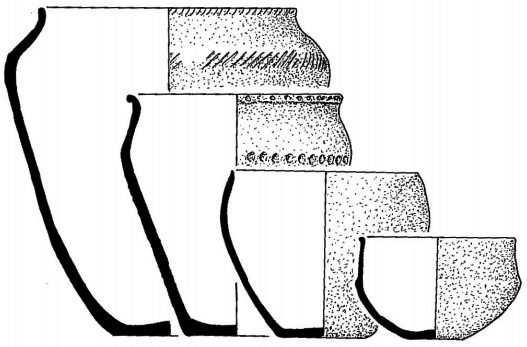

Middle – Late Neolithic pottery (c. 3000 – 2000 BC)

- e.g. Grooved ware/Peterborough ware

- Thick rimmed round based bowls.

- Highly decorated pottery with profuse impressions of twisted and whipped cord, reeds, sticks and the bones of small birds and mammals.

- Distinctive carination developed out of the carinated bowl forms of the earlier 3rd millennium.

- Shell, grog, veg tempered.

- Food vessels.

Peterborough Ware

Late Neolithic – Early Bronze Age (c. 2200 – 1500 BC)

- e.g. Collared/Cordoned Urns

- Bipartite or tripartite vessels.

- Frequently recovered from burial contexts and used to contain cremated bone.

- Developed from Peterborough ware.

- Heavy rim or collar, vertical or slightly inverted.

- Incised or impressed decoration incl. herringbone or chevron.

- Straight sided or slightly bowed body narrowing to a small flat base.

Collared Urn

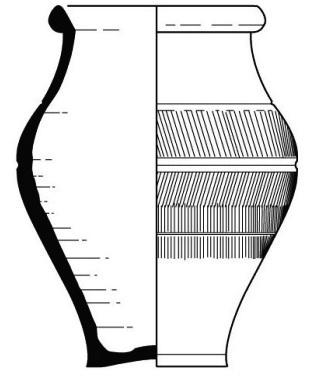

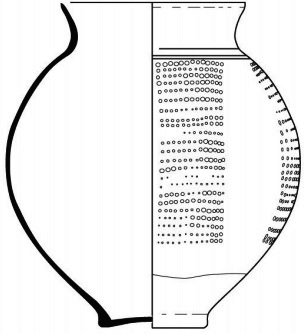

Beaker pottery (c. 2200 – 1800 BC)

-

- A highly decorated fineware, with a soft orange fabric. Two main types of decoration: all-over-decorated or combed-zoned.

- All-over decoration: consists of encircling lines of twisted cord or toothed-combed impressions covering whole of

outer surface. - Comb-zoned decoration: Bands of comb-impressed decoration, geometric motifs split by undecorated bands.

Beaker Pot

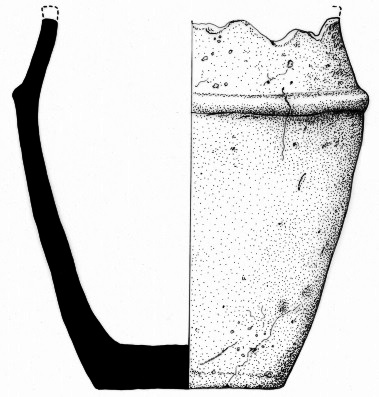

Middle Bronze Age (c. 1500 – 1000 BC)

- e.g. Deverel Rimbury pottery

- Heavy barrel and bucket-shaped urns.

- Smaller, finer globular urns.

- Straight sided, occasionally vertical.

- Decorated with vertical and horizontal cordons.

- Fingernail and finger tipped impressed decoration on rims and shoulder or on cordons.

- Mostly shell-tempered other tempers include flint and grog.

Deverel Rimbury

Late Bronze to Early Iron Age (EIA) (c. 1100 – 400 BC)

- Flint-tempered.

- Large rough storage jars.

- Finer bowls and cups.

- Little decoration, simple forms.

EIA pottery

- Increase in the variety of forms.

- Also flint-tempered.

- Some highly decorated and burnished.

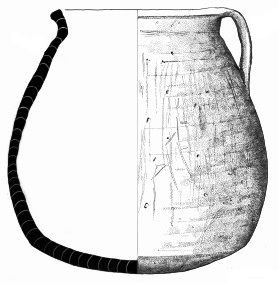

Middle Iron Age (c. 400 – 50 BC)

- Scored, scratched or wiped wares.

- Continued in the 3rd – 1st centuries and into Roman times.

- Large storage jars and bowl-shaped vases.

- Rough, random incised scoring/scratching vertical, diagonal or arched. Thought to be practical in purpose to aid handling rather than just decoration.

- Shell-tempered and some flint-tempered.

- Frilling on some rims.

Scored Ware

Late Iron Age (c. 50 BC – 50 AD)

Belgic Pottery

- A general term to describe cordoned jars, pedestalled cups and jars, butt beakers and, for the first time, wheel-thrown pottery.

- Initially imported into Britain from the 1st century BC continuing into the Roman period

- Vessels were predominantly produced in grog-tempered fabrics.

- While recovered in domestic assemblages the pottery is also known from cremation burials in south-east England.

Belgic

Gallo-Belgic pottery (c. 20 BC – 70 AD)

Gallo-Belgic pottery was being imported into Britain and produced in Verulamium and Colchester before 43 AD

- Terra Nigra, grey-black vessels, continued in fashion until the early 70s AD.

- Terra Rubra, orange-coated cream to buff vessels, scarcely survived the 50s AD.

- Produced in a standardised range of cups, dishes, and shallow platters with footrings and often stamped with the potter’s name.

- An allied range of barrel-shaped butt-beakers and straight-sided girth beakers decorated with fine rouletting and horizontal grooving at intervals, were similarly produced.

Gallo-Belgic

Roman Pottery (43 – C. 410 AD)

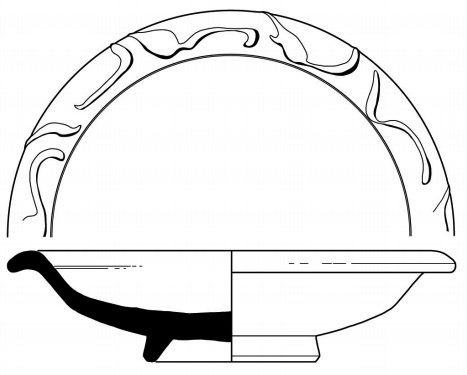

Samian (also known as terra sigillata)

- Fine red pottery with a glossy red slip. The fabric has a high iron content and is typically rich in calcium.

- The slip is made of very fine clay mixed with water. It contains a higher proportion of potassium and sodium, which allows it to melt onto the body of the vessel.

- The pottery is fired in an oxidising kiln and turns red.

- In double-chambered kilns, the Samian is heated twice; in the first stage, the pottery is fired in a reducing atmosphere and turns black; oxygen is allowed in during the second stage, turning the pottery red.

Samian

Why study samian?

- Dating: forms and name stamps are well-dated.

- Patterns of supply: plotting name stamps gives us trade routes and role of middlemen; wreck-sites are also useful.

- Organisation of pottery industries: many tasks involved; slippreparing, mould-making, stamp-making etc. Stamps give names of workshop ‘foremen’, workers and slaves, and show movement of potters and occasionally family relationships.

- Status: the proportion of decorated samian increases with site status.

- Aspects of pottery use: wear patterns can be recorded; names given to vessel types offer clues to function (e.g. acitabli – for oil and vinegar; salaria – salters; boletari – mushroom dishes).

- Decoration: use of certain motifs was apparently significant. Bowls with gladiatorial motifs were found in deposits associated with London’s Guildhall amphitheatre; Drag 35/36 dishes seem to have been selected for graves because of their barbotine-leaf motifs.

Samian Ware Stamps

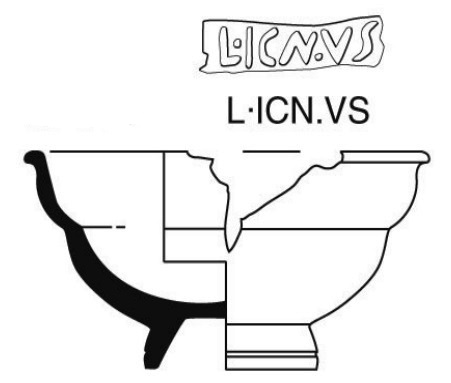

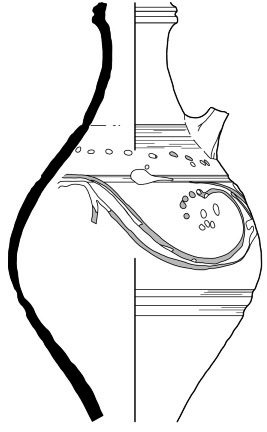

Mortaria

- Mortaria are bowls with a flange or hooked rim, a spout and grits on the internal surface. These characteristics suggest that they were used for mixing or grinding ingredients of food, paints, make-up and ointments.

- Mortaria were imported and made in Britain throughout the Roman period, and were made under the auspices of most major pottery industries.

- Mortaria were often stamped on the flange, adding to their potential as a dating tool.

- Pestles were mostly made from wood, but could also be made from amphora handles.

Mortaria

Nene Valley Mortaria (110 – 410 AD)

- Source: The Nene Valley in eastern England

- Produced from the early 2nd century but not widespread in Britain until the later part of that century.

- Fabric: Hard off white, sandy with red and black inclusions, can be colour-coated.

- Forms, flanged and beaded or with reeded rim.

- Concentrated in the East Midlands near manufacturing centres. Also present in the SouthEast (London) and Hadrian’s Wall. Few are found in western Britain.

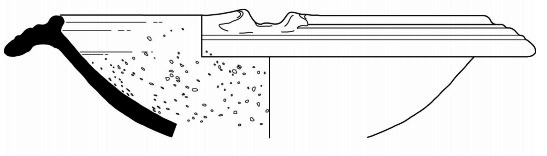

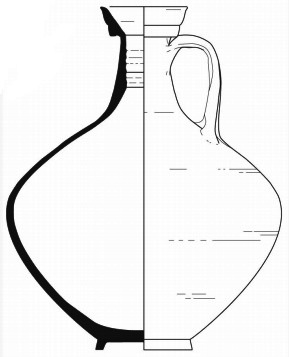

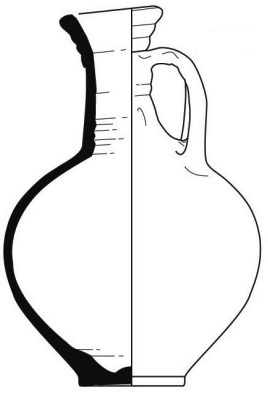

Flagons

- A narrow mouthed globular vessel type introduced to Britain in 43 AD. The earliest examples were imported or produced locally for the army.

- They were used to contain liquids decanted from amphorae.

- 1st and 2nd century examples have a characteristic light coloured fabric.

- If clays fired too dark, manufacturers coated the flagons in a pale slip, because they were supposed to be lightly coloured!

- In general, flagons become smaller in the 3rd and 4th centuries AD.

Roman Flagon

Hofheim Flagons: Imported or produced in Britain for the army c.43 – 70 AD. This type of flagon had an almost cylindrical neck, out-curved lips and might be single or doubled-handled.

Ring-neck flagons: a common type, they have a mouthpiece constructed of multiple superimposed rings; in the mid 1st century AD the neck-top was more or less vertical. By 2nd century AD the top ring lip thickened and protruded while the lower rings became fewer or degenerated into grooving.

Ring-neck Flagon

Flanged-neck flagons: were manufactured in a variety of fabrics, mostly colour-coated during the 3rd and 4th centuries AD.

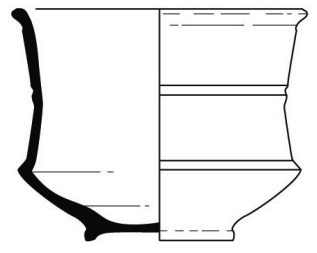

Coarse wares e.g. grey wares

- Small-scale production sites located in rural sites and larger settlements.

- Kilns site operational for as little as a few years only.

- Main source for utilitarian grey wares.

- Regionally uniform pottery traditions.

Grey Ware

Romano-British Fine wares

- Colchester colour-coated ware (120 AD – late 3rd century AD).

- New Forest colour-coated ware (260 – 370 AD).

- Nene Valley colour coated-ware (200 AD – late 4th century AD).

- Oxford red colour coated-ware (240 AD – early 5th century AD).

- Hadham Oxidised ware (200 AD – late 4th century AD).

Amphorae (singular: amphora)

- Amphorae are important chronologically. Their presence in late Iron Age high-status graves gives chronological control over a range of late Iron Age/early Roman material culture.

- They tell us about trade and the nature of long distance links, but also because they are closely linked to particular imported commodities.

- When found in burial contexts, they show the importance of alcohol to LIA and Roman burial practice.

Dressel 20 (10 – 260 AD)

- Manufactured in southern Spain (Baetica) between Cordoba and Seville.

- Fabric: yellow/off-white sandy, quartz, limestone, mica.

- Form: globular, small spike, rounded or angular rim.

- Contents: mainly olive oil.

- Probably the most widely distributed amphora type in Britain. This is partly because of its longevity and partly due to the importance of olive oil. Distributed to all major sites it is also even quite common on rural sites.

Saxon Pottery

Early Saxon pottery (c. 425 – 650 AD)

- In cemetery sites people are buried with grave goods. Decorated vessels tend to be found on cremation sites. Decoration on funerary vessels is very variable.

- 5th century pottery has linear designs – straight or curvilinear lines.

- Late 5th century bosses have straight or curvilinear designs.

- In the 6th century linear designs and stamping, later this becomes stamping and bosses.

- By the 7th century for the most part stamping is the only decoration.

Middle Saxon Period (early/mid 7th – mid 9th century AD)

This period is defined in particular by the arrival of Christianity.

Ipswich ware (end 7th century – c. 875 AD)

- Produced using a slow wheel that would appear to work like a turntable.

- Pitchers are found in areas well beyond East Anglia around the seaboard of Middle Saxon England. Cooking pots and other vessels are found close to Ipswich, rarely moving more than twenty miles beyond Ipswich.

Ipswich Pot – Hinxton Hall

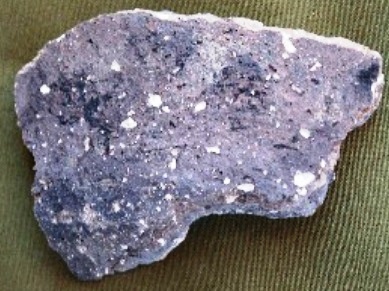

Granodiorite tempered pottery

- There are two kinds of temper that are particularly significant: rather dull greyish lumps of rock and bronze looking plate-like inclusions which are mica. The rock is igneous and the only source is Mountsorrel in Leicestershire. Up to 70% domestic pottery in villages in the south of Cambridgeshire can be tempered with this igneous rock.

Maxey ware

- Handmade shell-tempered pottery. It uses none of the new technological or cultural advances found in Ipswich ware. It has a few classic vessel types, such as pots with lugs on the side,

usually pierced to allow the suspension of the vessel. - Uncommon in most of Cambridgeshire apart from near Peterborough where it is frequently found as Maxey lies with in the ancient Soke of Peterborough.

Late Saxon (c. mid 9th – mid 11th century AD)

Thetford Ware

Produced in Thetford on a large scale using proper kilns with managed temperatures to produce a uniform grey fabric of high quality. Only the large storage vessels are handmade. Also manufactured outside Thetford at various sites including Ipswich and Norwich.

Thetford Ware

St Neots Ware

Shell-tempered and wheel-made but still fired in bonfire kilns or clamps. It appears in a multitude of colours that vary from black to pink to brown to red.

The fabric is soapy to the touch and the shell is finely crushed. The pottery was probably produced in various centres around St Neots.

St Neots Ware

Stamford Ware

An off-white, very fine, light firing fabric, wheel made and fired in kilns. It is also the first appearance of glazed indigenously produced pottery in this country since the Roman period. Glazed from 875 AD, no other major glazed ware emerges in this country until the 12th century, apart from a brief period in Winchester in the later 9th

Stamford Ware

Medieval Pottery

Early Medieval (c.1066 – late 12th century AD)

- The main St Neots, Thetford and Stamford ware pottery types persist beyond the Norman invasion. In addition some new fabrics emerge.

- By the middle of the 12th century St Neots ware goes into decline. Shelly-ware pottery from about c.1150 it is known as Northamptonshire Shelly ware or just SHW in this area. The

vessels increase in size but are less well finished and the shell inclusions are coarser than in St Neots ware. - Shelly wares are also produced in the Peterborough area however they are difficult to tell apart from the Rockingham forest industries, the Northamptonshire Shelly wares or

Lincolnshire Shelly wares. - Essex Micaceous Sandy wares are found all over South Cambridgeshire from the 11/12th century. The Essex potters are using micaceous clays producing brown and grey-brown

fabrics of variable quality, some wheel-made and not all kiln fired.

High Medieval (late 12th – mid 14th century)

The High Medieval period in pottery terms is a highly decorated period particularly jug forms where applied strips, pads and stamps are common. Some industries create polychrome

decoration using different coloured clays and slips to produce flamboyant decoration on jugs. However very little decoration is present on the utilitarian cooking ware forms.

Colne Ware (1200 – 1350 AD)

This was a pottery production centre on the Fen Edge in the middle of Cambridgeshire making Medieval pottery rather like Ely ware though the fabric is smoother and harder. As Colne becomes more developed later in the period it becomes more

distinct from Ely ware.

Colne Ware

Ely ware (1150 – 1350 AD)

One of the more recognisable local coarse fabric types is Ely ware, used for jars bowls and cooking pots and also for glazed jugs. Some of it is wheel-made, some is handmade, and the fabric usually has buff surfaces (but not always) and a blackgrey core, with some calcareous (white blobs) temper. Ely Ware is found in the Cambridgeshire fens up and down the rivers and as far north as Wisbech and Kings Lynn.

Ely Ware

Further Reading

Study Group for Roman Pottery: www.romanpotterystudy.org

Medieval Pottery Research Group: www.medievalpottery.org.uk

Prehistoric Ceramics Research Group: www.pcrg.org.uk

This step by step guide to archaeological techniques is one of a series prepared by Jigsaw – a network of Cambridgeshire groups working alongside Oxford Archaeology East. The guides are available for download from the Jigsaw Website. Copyright in these guides belongs to Jigsaw and the authors, including Paul Booth (OA South)